The size of chicken food pellets can have a significant impact on the feeding efficiency of laying hens. Pellet size not only affects the ease with which hens consume feed but also influences digestion, nutrient absorption, and overall flock performance. Research and practical observations indicate that uniform, appropriately sized pellets encourage hens to consume feed more consistently, reducing wastage and improving productivity.

The Role of Pellet Size in Feed Consumption

Hens tend to prefer pellets that are neither too large nor too small. Oversized pellets may be difficult to consume, leading to slower feed intake and uneven nutrient distribution among the flock. On the other hand, excessively small pellets or mash can increase feed wastage as hens scatter the feed while eating. By adjusting pellet size to match the age and breed of the hens, farmers can achieve better feed conversion ratios and healthier flocks. Chicken food pellets that maintain consistent size and texture help create uniform feeding behavior, which is especially important in large-scale layer operations.

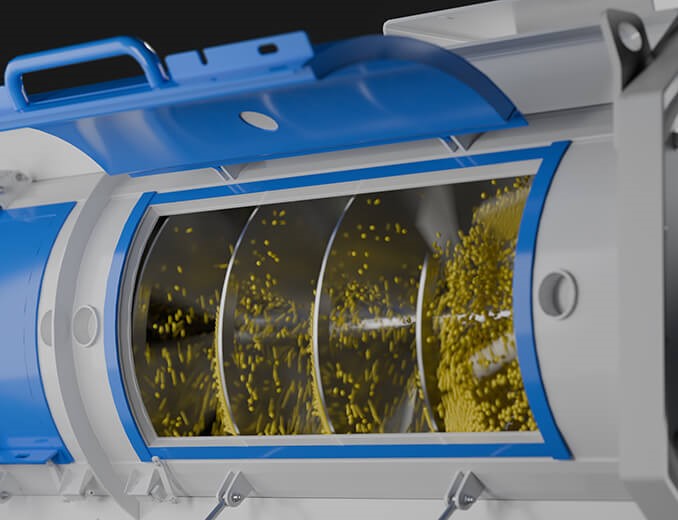

Enhancing Pellet Quality Through Advanced Cooling Systems

Proper cooling of pellets after production ensures they maintain their shape and stability. Optional single-deck and multi-deck cooling systems, combined with low-emission air networks, provide complete and uniform cooling of both pellets and mash. This process not only preserves feed quality during storage and transport but also enhances feeding efficiency, as hens receive pellets that are firm and less prone to breaking. When pellets retain their intended size and consistency, hens can consume them more easily, leading to improved digestion and nutrient absorption.

Practical Implications for Layer Feed Efficiency

Optimizing pellet size also aligns with broader goals of cost reduction and sustainability. By minimizing feed wastage and ensuring hens receive nutrient-rich pellets, farms can reduce overall feed expenses and lower environmental impact. Uniform chicken food pellets support better flock health, reduce selective feeding, and enhance the consistency of egg production. When combined with well-designed cooling and handling systems, the advantages of proper pellet sizing are amplified across the production cycle.

Conclusion

In conclusion, attention to pellet size is a critical factor in maximizing feeding efficiency and flock performance. Companies like FAMSUN offer comprehensive layer feed solutions that include precise pelletizing equipment, uniform cooling systems, and optimized handling technologies. Their approach enables farms to maintain high-quality chicken food pellets consistently, supporting global projects and large-scale operations with effective, low-carbon solutions. With a focus on reducing costs, improving efficiency, and maintaining feed quality, FAMSUN continues to deliver reliable support for poultry producers worldwide.